How To Repair Mortar Cracks

Repairing of masonry cracks (crack width < 1 cm)

RELATED MATERIALS

DUROCRET Polymer-modified cement mortar

RAPICRET Fast-setting patching mortar

UNICRET Mortar for rendering and masonry

UNICRET-FAST Fast-setting, white repairing mortar

ADIPLAST Polymer latex for multiple improvements of mortars

FIBERGLASS MESH Fiberglass mesh for render reinforcing

I. NATURE OF THE PROBLEM – REQUIREMENTS

Simple cracking in non-supporting masonry elements (eastward.g. walls) causes strength issues as well equally beingness unsightly.

2. SOLUTION

The materials used to repair such cracks must take the following properties:

Efficient bonding to bricks.

Sufficient workability, to facilitate the filling of cracks.

Low shrinkage during setting, so that they do not fissure every bit they harden.

a) Repair of cracks

Suitable materials:

DUROCRET, polymer modified cement mortar, or

RAPICRET, fast setting patching mortar, where rapid piece of work is required.

b) Repair of plaster

Suitable materials:

UNICRET, cement-lime mortar, reinforced with ADIPLAST polymer latex, or

UNICRET-FAST, fast-setting cement-lime mortar, reinforced with ADIPLAST polymer latex, where rapid work is required and the surface is not extended.

3. APPLICATION

The complete repair procedure is as follows:

a) Repair of cracks

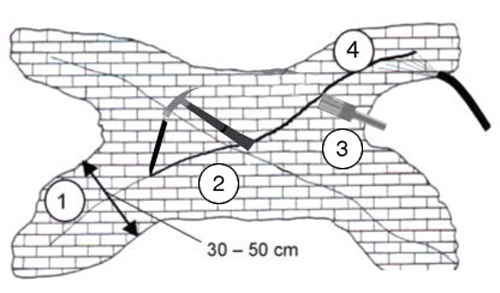

The plaster is removed at a total width of thirty-fifty cm along the unabridged length of the fissure (15-25 cm on each side of the fissure).

The cracks are widened along their unabridged length past breaking the surrounding bricks with a abrupt tool.

The cracks are thoroughly cleaned compressed air or with a brush.

Afterward, the substrate is thoroughly dampened.

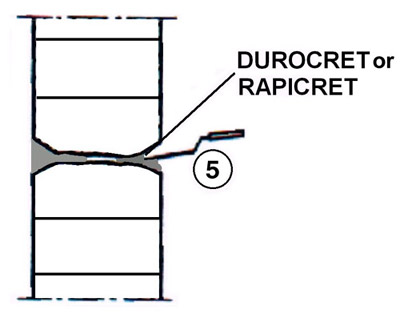

DUROCRET polymer modified cement mortar or RAPICRET fast-setting patching mortar is introduced, every bit securely as possible into the widened fissure, using a gauging trowel. These mortars are to be mixed with h2o only. After the cloth has hardened, repair of the plaster can follow.

b) Repair of plaster

The substrate must be advisedly cleaned of loose particles, dust etc. and dampened thoroughly with water.

The showtime coat of plaster is applied, using UNICRET cement-lime mortar or UNICRET-FAST fast-setting cement-lime mortar, reinforced with ADIPLAST polymer latex. ADIPLAST is added to the mixing water in the ratio of ADIPLAST : h2o = 1 : iii.

While the outset coat is still fresh, a strip of glass mesh, as wide every bit the surface area of the removed plaster is laid and lightly pressed onto the first coat.

Once the starting time glaze has set up, the final plaster coat of UNICRET cement-lime mortar or UNICRET-FAST fast-setting cement-lime mortar is applied. The product is now mixed with water just. In example that a plaster of higher strength is desired, ADIPLAST polymer latex is added to the mixing water in the ratio of ADIPLAST : water = i : v.

IV. REMARKS

Temperature during application must exist betwixt +50C to +350C.

Material that has started to ready must non be softened again with water.

During summer months it is recommended that the plaster is dampened after being practical, to protect it from aridity due to loftier temperatures.

Consult the directions for rubber apply and precautions written on the packaging.

How To Repair Mortar Cracks,

Source: https://www.isomat.eu/solution/repairing-of-masonry-cracks-crack-width-1-cm-en/

Posted by: meyerdencen1959.blogspot.com

0 Response to "How To Repair Mortar Cracks"

Post a Comment